Light Burned Magnesium Oxide for Industries

Light burned magnesium oxide with reactivity and purity suitable for various applications.

Light Burned Magnesium Oxide for Industries

Light burned magnesium oxide with reactivity and purity suitable for various applications.

Highly-Dispersive Magnesium Oxide

Magnesium oxide has features as high purity (99.9%) and high dispersibility.

Electro-Fused Magnesium Oxide for Electrical Heater

Electro-fused magnesium oxide used for insulating filler of heating elements.

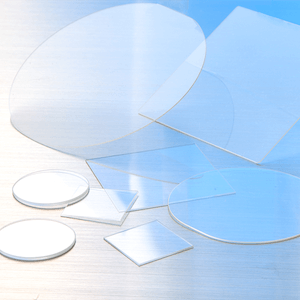

Single Crystal Magnesium Oxide Substrate

MIRACRYSTAR® is the largest crystal MgO that has the purity of 99.9%.

High Purity Magnesium Oxide Ceramics Products

High purity magnesium oxide ceramics products made of 99.99%-pure magnesium oxide material

Dense Magnesium oxide ceramics

Magnesium oxide ceramics made by adding yttrium oxide to magnesium oxide to make it denser.

Electro-fused Calcium Oxide

Calcium oxide with slake-resistance improved by means of the electro-fused method.

Silicon Carbide Whisker

Silicon carbide whisker used as reinforcement materials for ceramics, metals and plastics