Hello! Do you have any questions about Tateho Chemical Industrial's products? 😊

Please feel free to ask us about any questions regarding our products.

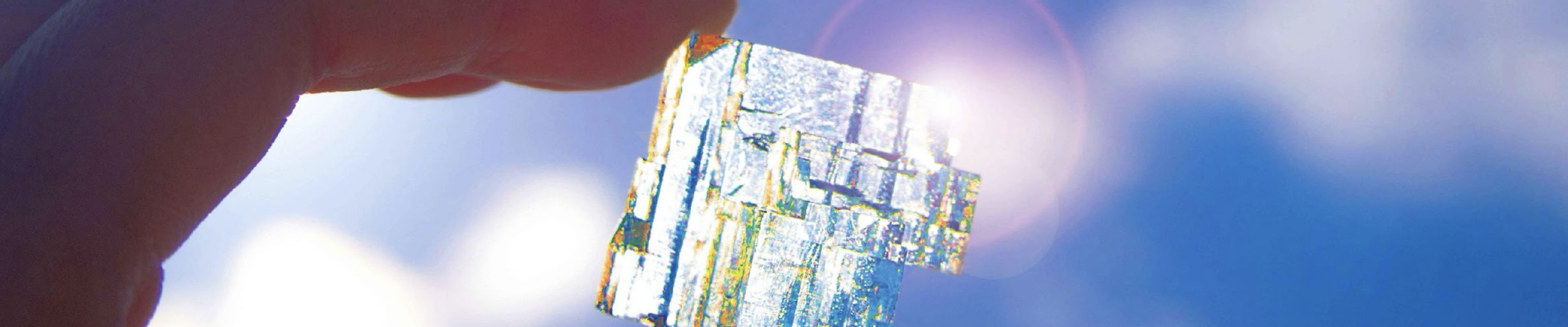

High-quality magnesium oxide ceramics produced through integrated production from raw materials to products

The magnesium oxide is used as a refractory under severe condition. Because its melting point (3099K) is the highest in the oxide and it is excellent in thermal conductivity (53W・m-1・K-1).

The magnesium oxide is superior in corrosion resistance in the molten metal. The magnesium oxide can be used for a lot of metals compared with the aluminium oxide. Especially, it is suitable for the calcination of lead zirconate titanate (PZT).

Tateho manufactures magnesium oxide ceramics products of various shapes, such as setters, crucibles and saggers in a continuous process from raw materials to products.

| Grades | TATECERA®️ | |||

|---|---|---|---|---|

| SMG#1 | SMG#2 | SMG#3 | ||

| Standard size (mm) | 160×160×5t | 160×160×5t | 130×130×5t | |

| Chemical compotision | MgO(%) | 99.87 | 99.77 | 99.78 |

| CaO(%) | 0.04 | 0.05 | 0.05 | |

| SiO2(%) | 0.01 | 0.01 | 0.02 | |

| Al2O3(%) | 0.04 | 0.04 | 0.02 | |

| Fe2O3(%) | 0.03 | 0.02 | 0.02 | |

| ZrO2(%) | 0.01 | 0.08 | 0.10 | |

| B(ppm) | 10 | 10 | 10 | |

| Physical properties | Apparent porosity (%) | 24.7 | 16.5 | 3.0 |

| Apparent density (103kg・m-3) |

3.6 | 3.4 | 3.4 | |

| Bulk density (103kg・m-3) |

2.7 | 2.8 | 3.4 | |

| Water absorption (%) | 9.2 | 5.9 | 0.9 | |

| Three point bending strength (MPa) | 10.4 | 44.6 | 80.7 | |