Hello! Do you have any questions about Tateho Chemical Industrial's products? 😊

Please feel free to ask us about any questions regarding our products.

Tateho began with the salt industry.

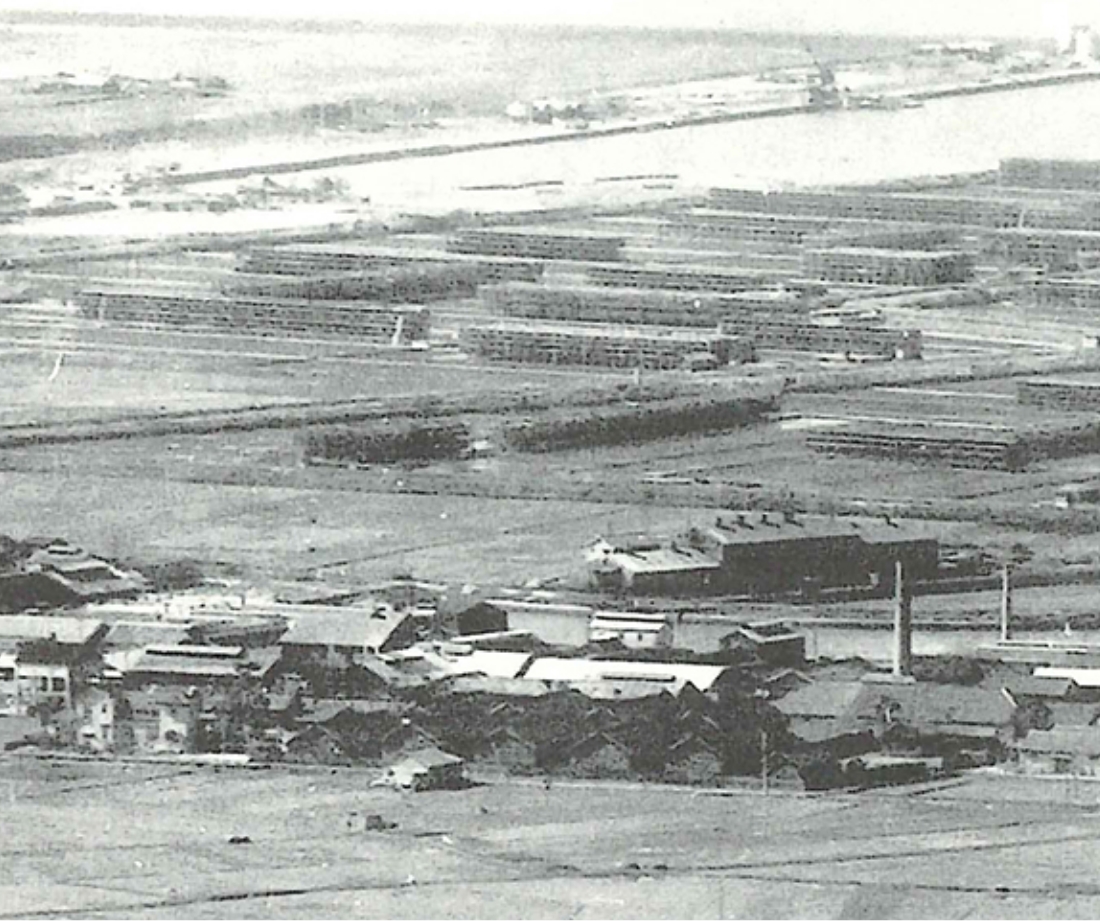

The salt industry has been conducted in Ako since the Nara period (710-794), and during the Edo period (1603-1868), the Ako clan was supported by large-scale Irihama-style salt fields.

The Ako Nishihama Salt Industry Association, which inherited this technology, used to dispose of a large amount of bittern left over after salt was extracted from seawater. In 1948, the salt industry cooperative established a chemical synthesis division to produce magnesium oxide from the bittern. Later, in 1966, the company became independent as Tateho Chemical Industry Co., Ltd.

Magnesium oxide is important as a material for refractory bricks used in the production of iron and cement because it is heat-resistant. Before the war, Japan imported magnesium carbonate ore from abroad to produce magnesium oxide. However, when World War II broke out, the supply of materials from overseas stopped, and Japan’s steel industry fell into a crisis. Meanwhile, in Ako, a large amount of bittern, which remained after extracting salt from seawater, was being discarded. In 1951, the Ako Nishihama Salt Industry Association, the predecessor of Tateho, succeeded in producing high-purity magnesium oxide from this bittern, receiving much acclaim.

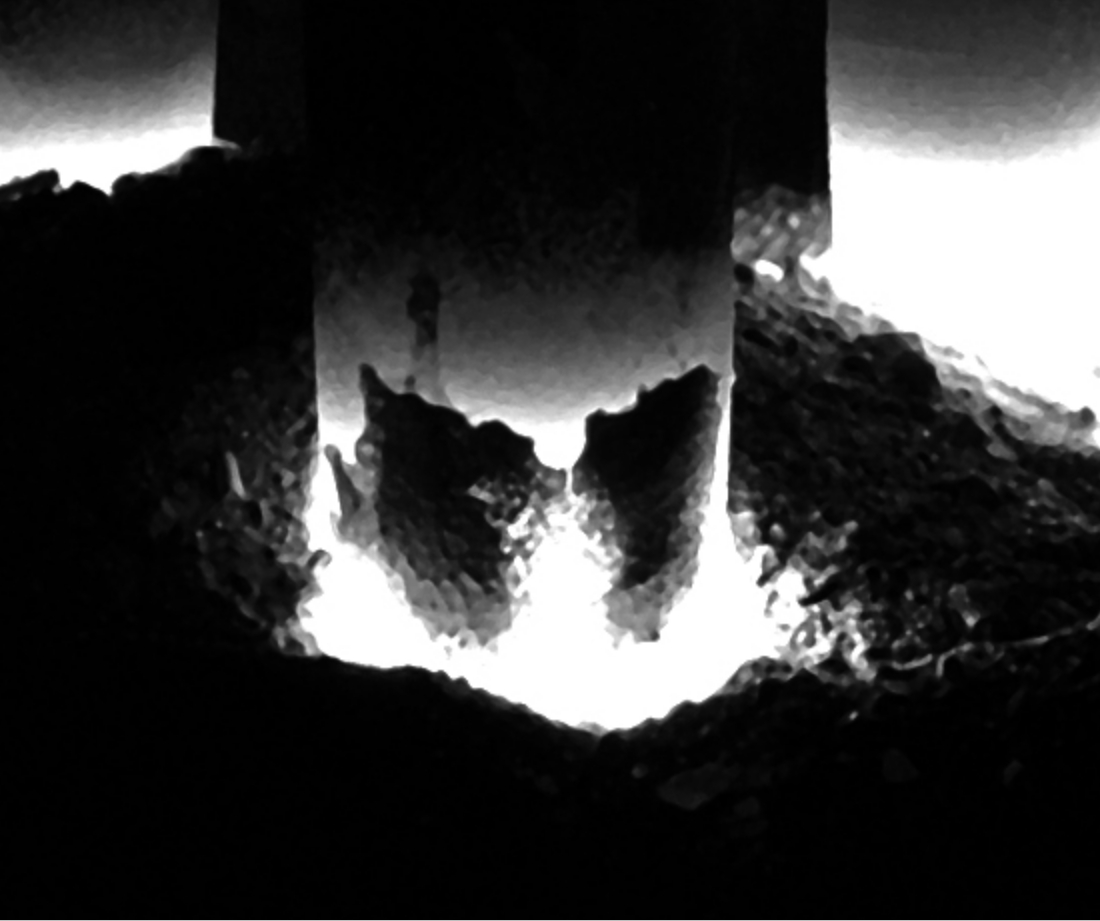

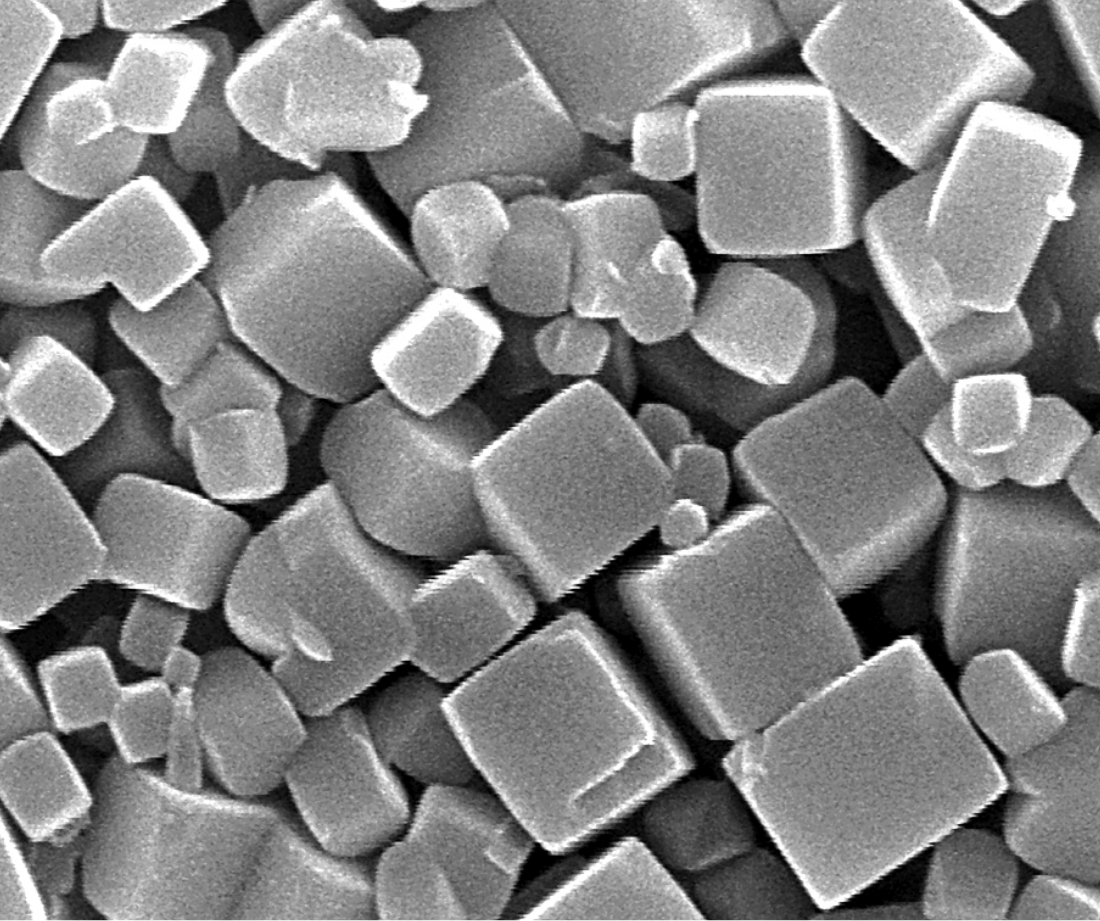

In 1960, Ako Seawater Industries Co., Ltd., the predecessor of Tateho, became the first in Japan to industrialize fused magnesium oxide by melting magnesium oxide through arc heating, which significantly grew the crystals. This fused magnesium oxide improved the performance of refractory bricks, leading many companies to enter the production of fused magnesium oxide, thereby supporting Japan’s steel industry. When cheaper fused magnesium oxide from China began to be imported for refractory brick production, domestic manufacturers withdrew. Currently, Tateho is the only company in Japan that continues to produce fused magnesium oxide.

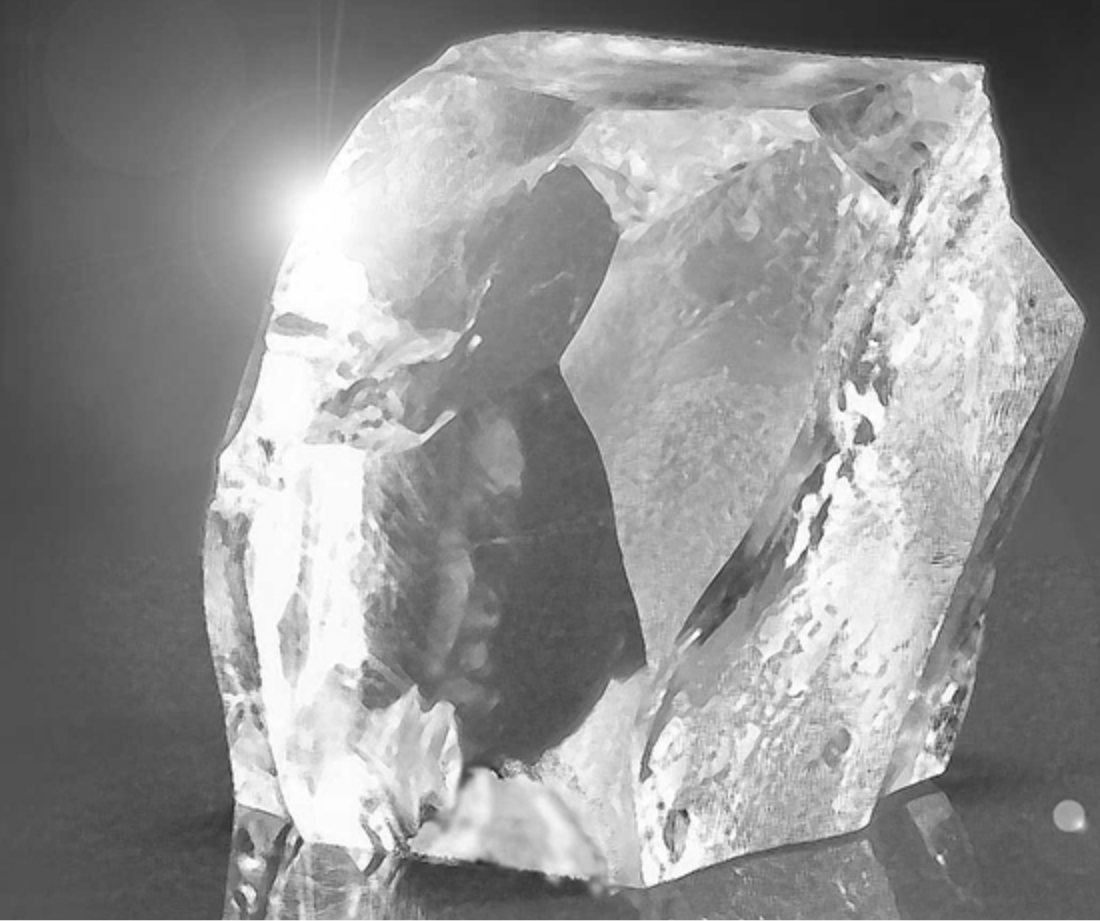

The enlargement of magnesium oxide single crystals has been considered difficult due to its high melting point and high vapor pressure. However, in 1968, using its unique crystal growth technology, Tateho successfully produced the world’s largest magnesium oxide single crystal. Substrates made from this single crystal have properties that match the lattice constants and thermal expansion coefficients of the films, making it easy to create epitaxial films. Therefore, these substrates are used in universities and research institutions for thin film formation of advanced materials such as high-temperature superconducting films, ferroelectric films, magnetic films for MRAM, and diamond films, becoming the industry standard.

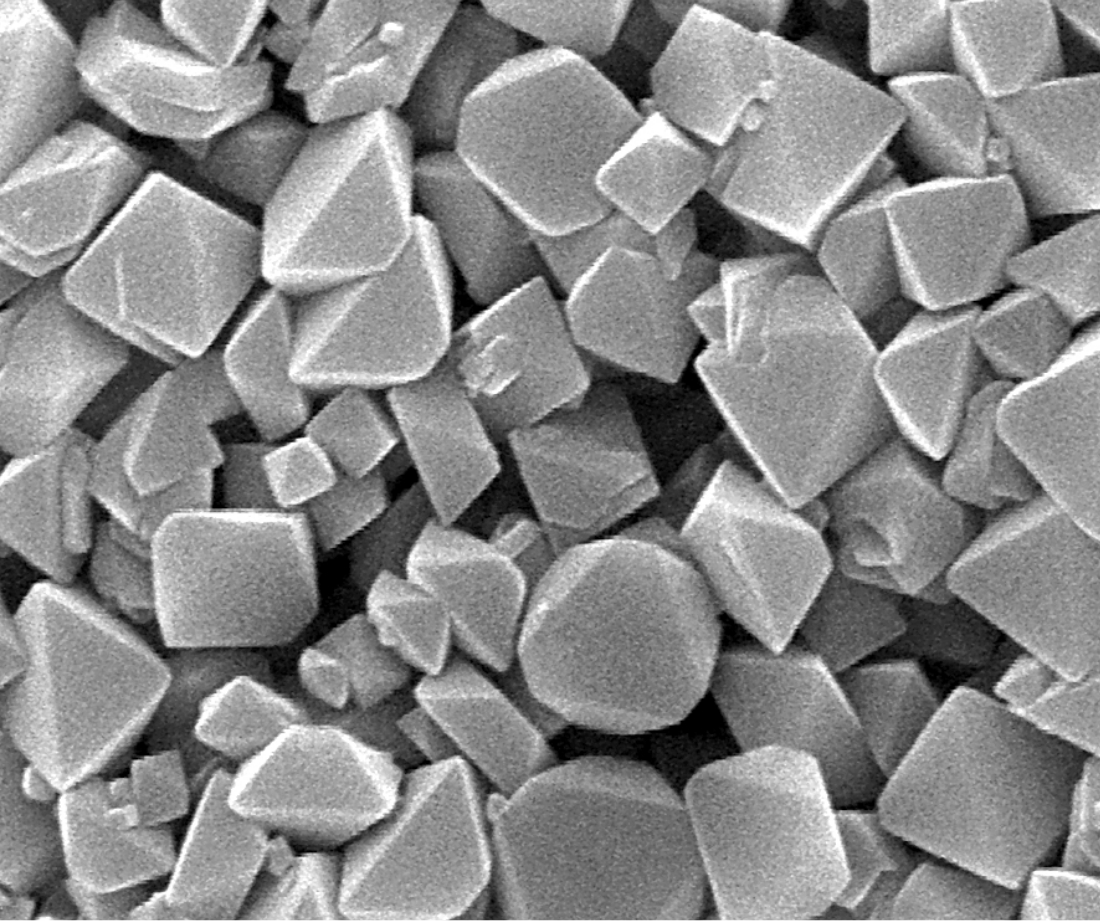

Grain-oriented electromagnetic steel sheets, used in transformers necessary for power transmission, were invented in the United States and their performance was enhanced in Japan. In 1969, it was discovered that using magnesium oxide produced by Tateho as an annealing separator improved the performance of electromagnetic steel sheets. Tateho’s magnesium oxide, produced with delicate control, became known as “magic powder” and started being used worldwide. It remains a flagship product, holding a 40% share of the global market.

To meet the societal demand for making plastic products flame-retardant without causing dioxin issues, Tateho successfully developed a non-halogen flame retardant in 1993 by combining magnesium with zinc to alter the properties of magnesium hydroxide. Furthermore, in 1997, Tateho developed a flame retardant that could be used in semiconductor encapsulation materials, which previously could not use magnesium hydroxide, providing a top-quality flame retardant.

In 2008, Tateho successfully produced ultra-high purity (99.99% or higher) magnesium oxide from a liquid phase for the first time. Due to its minimal impurities, it is used in electronic materials that require high purity.

In 2014, Tateho developed a chemical heat storage material capable of storing high-temperature waste heat and transporting it. This technology applies a method of controlling the dehydration reaction temperature by adding metal salts. It is expected to become an innovative technology that can promote energy conservation not only within companies but also across entire cities.

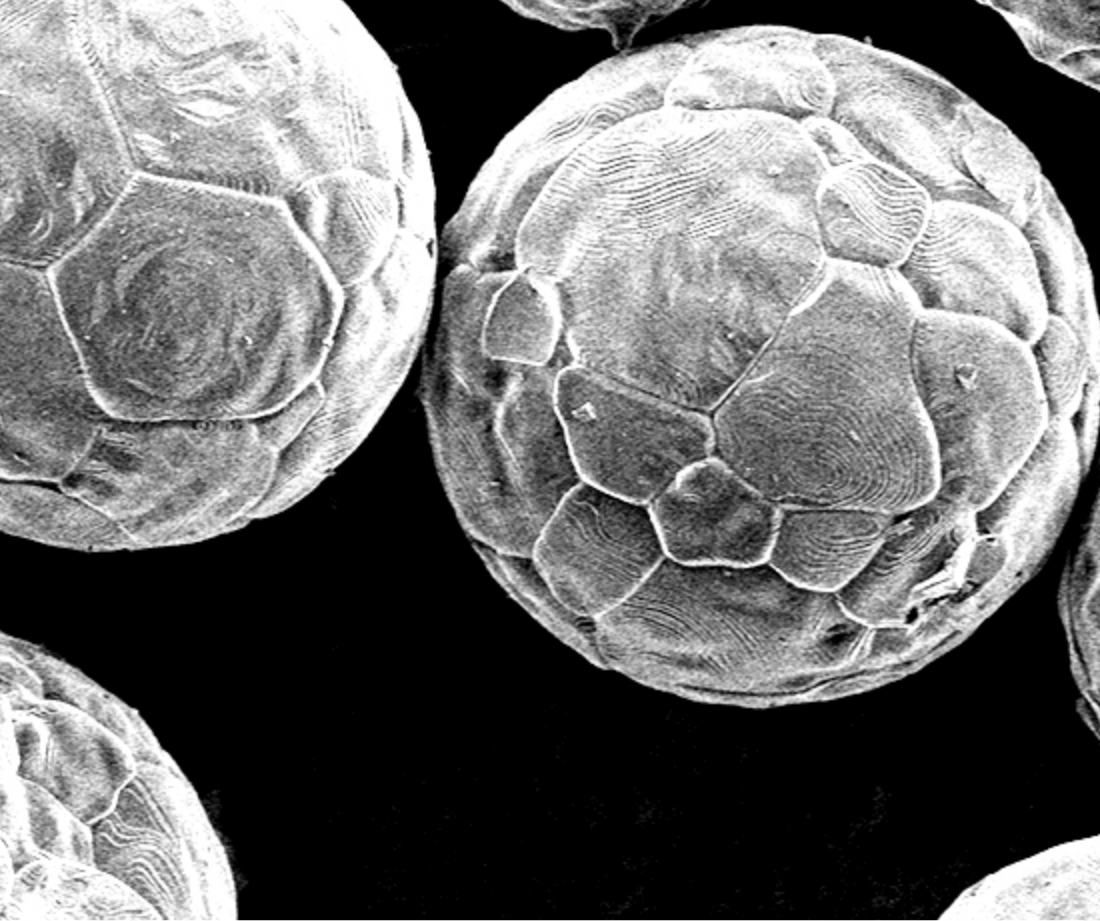

In 2021, Tateho developed spherical magnesium oxide fillers that achieve higher thermal conductivity than spherical aluminum oxide fillers by adding them to polymer materials. They succeeded in manufacturing spherical particles with water resistance equivalent to that of aluminum oxide, overcoming the previous drawback of magnesium oxide. As electronic components generate more heat due to increased power and speed, these fillers are expected to be used in heat dissipation materials necessary for thermal management.