Hello! Do you have any questions about Tateho Chemical Industrial's products? 😊

Please feel free to ask us about any questions regarding our products.

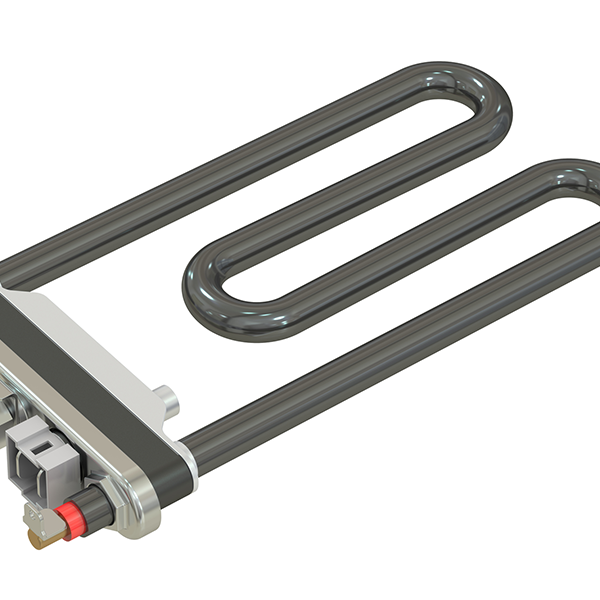

Sheath heaters are heaters with heating wires covered with metal pipes. It is a safe and secure electric heating component with low risk of electric leakage and electric shock.

They are widely used in household appliances such as coffee makers and electric kettles. Additionally, high-performance heaters are used in industrial equipment for mold heating and seal welding.

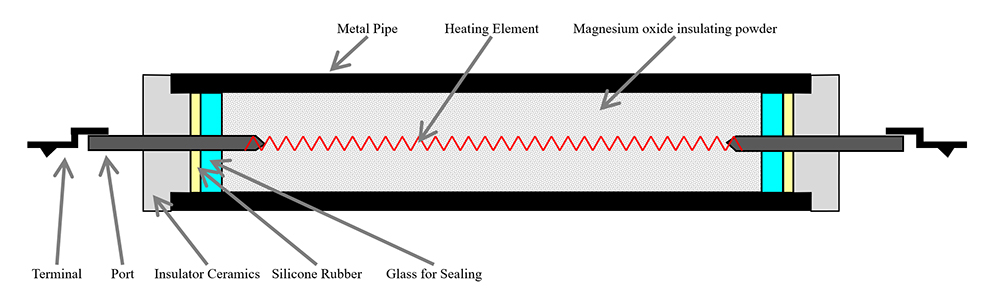

It mainly consists of a heating element (nichrome wire), a metal pipe, and an insulating material. The structure is as shown in the diagram below.Magnesium oxide is filled as an insulating material.

Magnesium oxide is used as a filler material because it is relatively inexpensive and has high thermal conductivity and insulation properties.

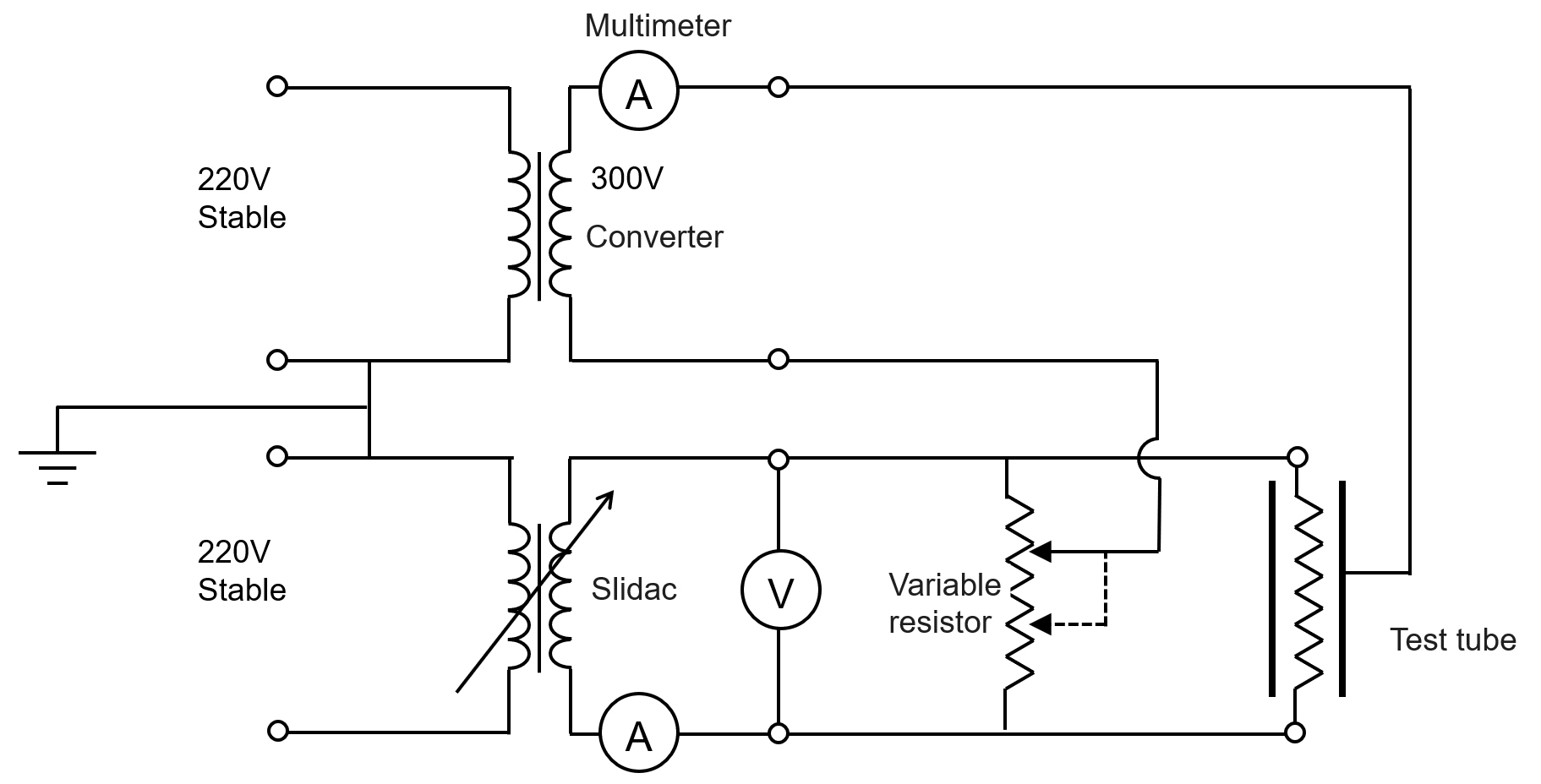

Measure the resistance between the terminals of the sheathed heater and inspect the heating wire for damage. Next, conduct an energization test by passing electricity between terminals to see how much heat is generated, and check for leakage current. Leakage current is the current that leaks out of the pipes when energized. The lower this current is, the safer the product. It is an important evaluation of sheath heaters. To measure the leakage current, the following circuit must be assembled to separate it from the current of energization.

We evaluate the flow rate and tap density of magnesium oxide powder used as an insulating material. Flow rate is a measure of fluidity and is expressed as the number of seconds it takes for a given amount of powder to pass through a hole. Good fluidity shortens the time required to manufacture heaters, thereby improving production efficiency. Tap density is a measure of fillability and is expressed as the density of the powder when it is packed in a container and subjected to vibration. Fillability is important because it affects heater performance. In general, higher fillability results in higher density inside the heater and better heater insulation performance. We have developed a tap & flow measuring device that realizes highly accurate and stable measurement, utilizing our accumulated know-how, and sell it to manufacturers of sheath heaters and others.

In 1900, a soft magnetic material that easily magnetizes when electricity is applied was discovered by Hadfield. In 1934, grain-oriented electrical steel, which has high magnetic properties in a specific direction, was invented by Goss. Grain-oriented electrical steel sheets began to be manufactured by the American company Armco in 1935, and production started in Japan in 1958. Subsequent research in Japan led to the invention of high magnetic flux density grain-oriented electrical steel sheets in 1965.

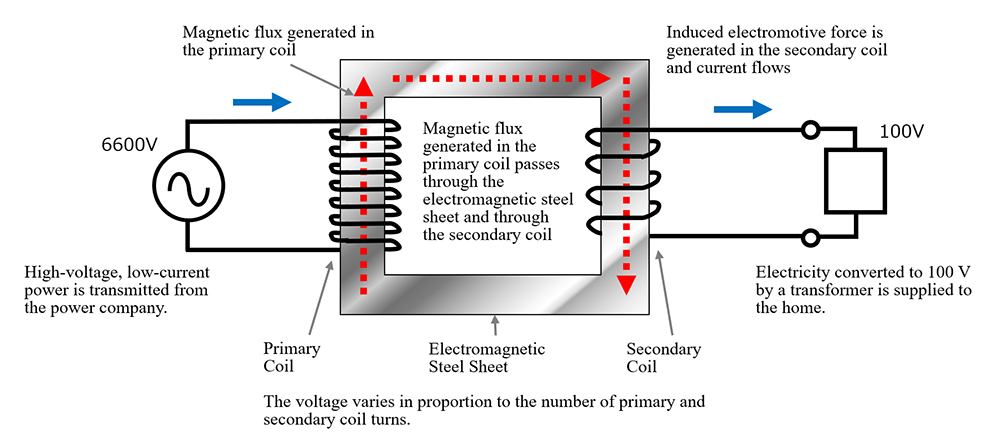

Grain-oriented electrical steel sheets is mainly used in transformers. Transformers are devices that regulate voltage. Electricity is transmitted from power plants at a high voltage of 6600V and is used in homes after being transformed to 100V or 200V. This voltage conversion is achieved using transformers. On the other hand, non-oriented electrical steel sheets is used in motors.

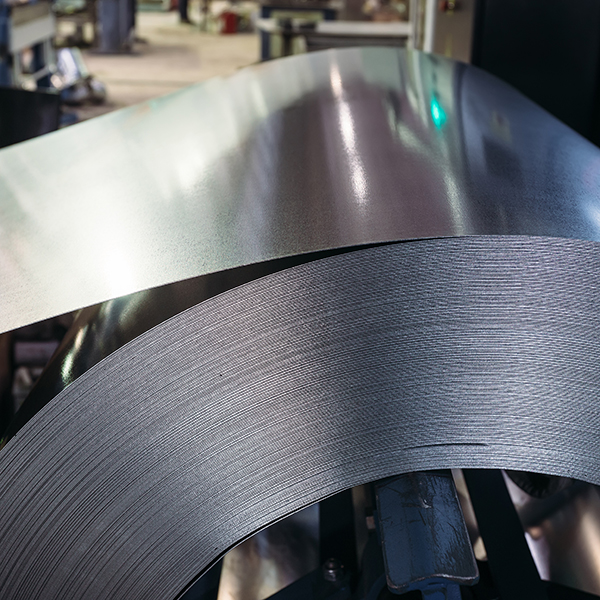

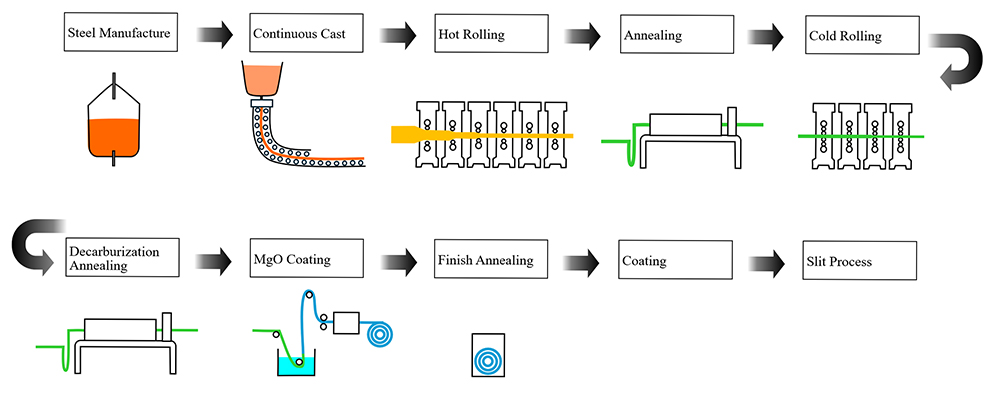

Grain-oriented electrical steel sheets are manufactured by the process shown in the figure below. Magnesium oxide is applied to steel sheets after decarburization annealing, and is used as a coating material (annealing separator) to prevent fusion between coiled steel sheets during finishing annealing.

Magnesium oxide applied to the surface of the steel sheet reacts with iron to form forsterite, which not only prevents anti-seizure but also significantly affects iron loss and magnetostriction. When TATEHO's magnesium oxide is used as a coating material for grain-oriented electrical steel sheets, It achieves the world's highest quality electromagnetic properties, earning it the nickname 'magic powder'.