-

- Learn about Tateho's Technology

Who We ARE

Magnesium Oxide (MgO) Synthesis Technology Made by the Salt Manufacturing

Chemical Synthesis Technology

In 1951, when it was difficult to gain magnesium oxide resources from overseas, Tateho has succeeded in producing high-purity magnesium hydroxide from the bittern, by-product of the salt manufacturing process.

In the following year, Tateho succeeded in industrializing the low calcium MgO by receiving government subsidies, and gained high evaluations from industries.

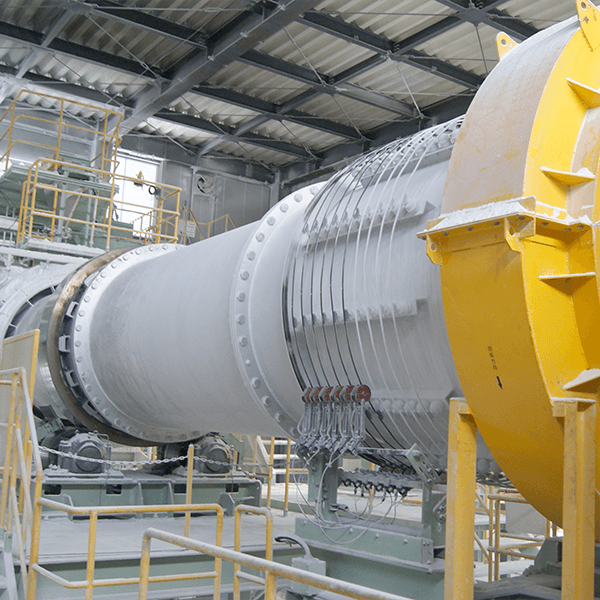

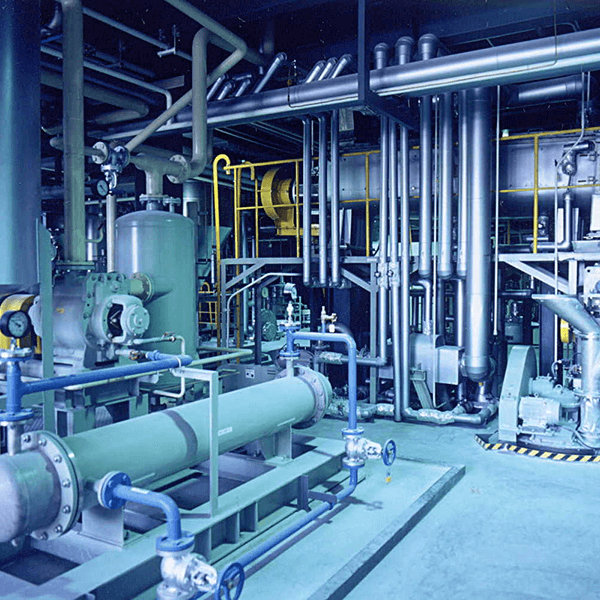

Experienced Long Standing Electro-fused Technology Pioneered in Japan

Electro-fused Technology

In 1960, Tateho succeeded in the industrialization of electro-fused MgO for the first time in Japan.

Today, Tateho is the only electro-fused MgO manufacturer in Japan. Tateho provides furnace manufacturers the highly crystalline electro-fused MgO produced using the technology cultivated over many years, and Tateho has earned the trust of many customers.

World's Highest Firing Technology

Firing Technology

Our MgO for electrical steel sheets is described as "a magic powder", because is indispensable material for manufacturing high grade electrical steel sheets. Precise calcining technology is required to manufacture such MgO.

We manufacture products by our world-class calcining technology, and earn the trust of our customers.

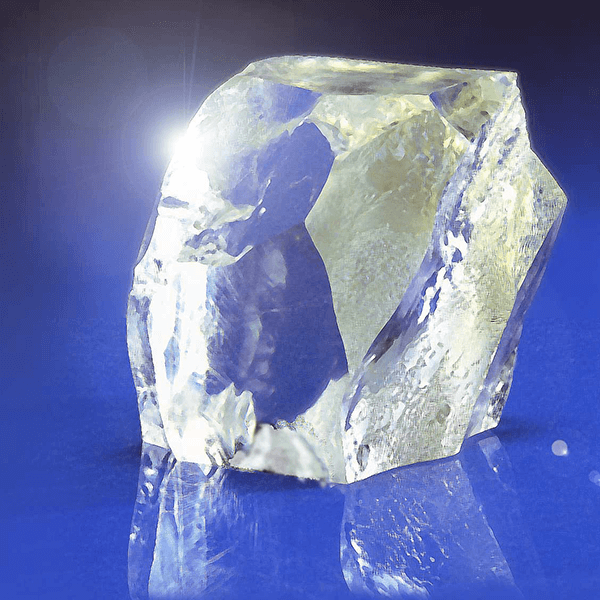

Crystal Growth Technology for Manufacturing the Largest Single Crystal in the World

Crystal Growing Technology

Forming large, single-crystal MgO had been considered difficult, given the material’s extremely high vapor pressure and the high melting point required.

Yet, as a specialized manufacturer in MgO, in 1968, Tateho achieved the world’s first success in commercializing large single crystals by utilizing its proprietary electro-fused and crystallization technologies.

Our MgO single crystal is the industry standard which is widely used as a substrate for thin film of state-of-the-art materials such as high-temperature superconducting film, ferroelectric film for MRAM, diamond film, etc.

Unique Composite Technology

Composite Technology

To respond to the world's demand to render plastic products flame-retardant without causing dioxin problems, we succeeded in developing high performance non-halogen flame retardant magnesium hydroxide that is changed physical properties by complexing Zn with Mg.

Magnesium hydroxide couldn’t be used with semiconductor encapsulants before, but in 1997, we developed a flame retardant that can be applied to semiconductor encapsulants by using crystal shape control technology and high purification technology. As such, we are able to offer such a high-quality flame retardant.

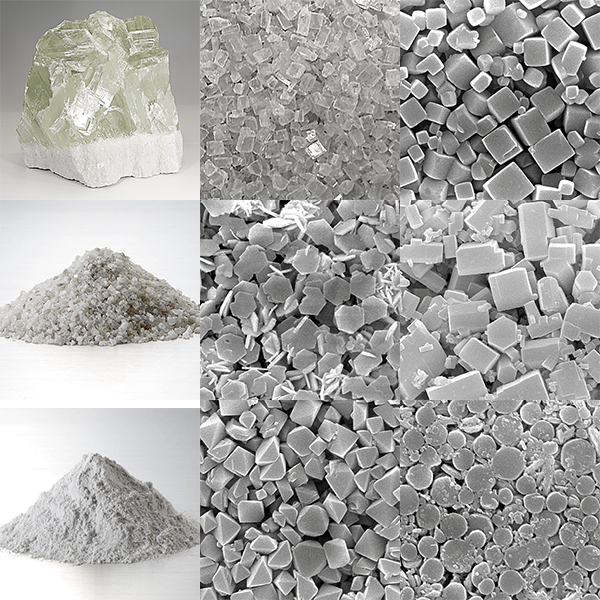

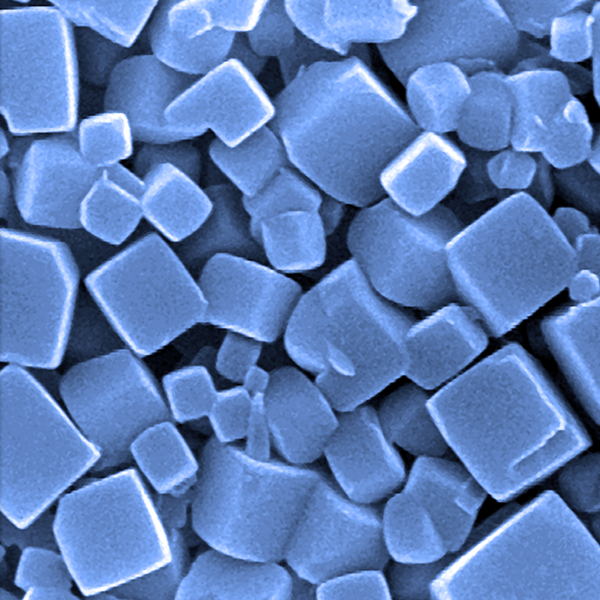

Particle Controlling Technology to Produce Wide Range of Optimization

Particle and Shape

Controlling Technology

Tateho produces MgO particles of several centimeters to several tens of microns by grinding crystal created by fusion, and also produce submicron particles to several microns particles by crystal precipitation from liquid.

There are no other manufacturers that combine these two technologies. By matching these technologies, we can meet a wide range of customer’s demands. Tateho can produce particles of various shapes such as cubic, plate, rod, octahedral, spherical of MgO.

High Purity Technology for Producing the Highest Purity MgO

Purifying Technology

Tateho succeeded in producing ultra-high purity (99.99% or more) MgO from liquid phase in 2008.

Ultra-high purity magnesium oxidized by vapor phase method has existed before. However, Tateho is the first manufacturer to industrialize ultra-high purity MgO exceeding 4N purity by precipitating from the liquid phase.

As it hardly contains impurities, it is used for electronic materials and others that require high purity.

Challenging into the Future with Technology

Never-Ending Challenges

Tateho Chemical continues research and development that innovates in future life, centering on materials related to heat and electricity.